Using the integrated technology of LED electro-optic source, according to major Intelligent factory lighting The characteristics of semiconductor luminescence, ingenious circuit design and unique lighting geometric appearance, major Intelligent factory lighting It can save more than 80% of electricity, realizing effective energy saving. The ultra long service life is up to 50000 hours, which can be used well in various special environments (such as low temperature and high temperature conditions). It solves the problems of low power and insufficient brightness of semiconductor electric light source in the lighting field, and shows excellent high brightness characteristics. There is no need for ballast, no starting difficulty, complete overcurrent, overvoltage, short circuit, temperature, surge protection, and its lighting optical performance is brighter and more complete than 75W/400W/1000W metal halide lamp.

Considering that street lamps are conductors, one way is major Intelligent factory lighting Combination of external lightning protection and internal lightning protection. As the material of street lamp is conductor, it is equivalent to lightning rod, and downlead and grounding grid need to be installed in the design. These systems constitute the external lightning protection system. After the completion of the external lightning protection system, the fire and personal safety accidents caused by the direct lightning stroke of the street lamp can be avoided. After the completion of external lightning protection, the internal lightning protection system can protect the equipment by grounding and setting voltage protection. major Intelligent factory lighting The internal lightning protection system is ready to prevent induced lightning and other forms of overvoltage intrusion, which may damage the power supply. This is also beyond the protection of external lightning protection system. Therefore, the built-in internal protection and external protection can complement each other.

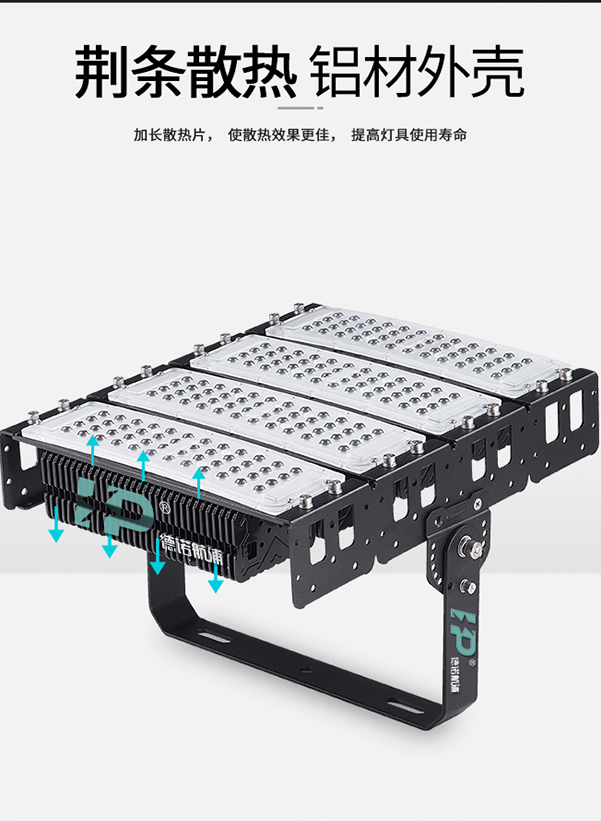

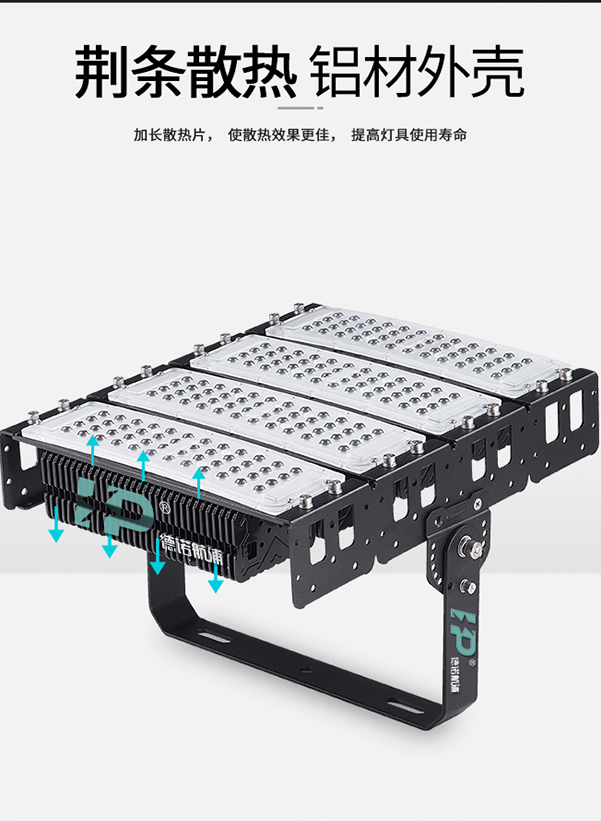

1. Strong anti-static capability: LED with strong anti-static capability has a long service life. 2. Brightness: The price of LED varies with its brightness. 3. Wavelength: LEDs with the same wavelength and color are expensive. 4. Luminescence viewpoint: LEDs for different purposes have different luminescence viewpoints. 5. LED chip: major Intelligent factory lighting The illuminant of is a chip, and the price of different chips varies greatly. 7. Colloid: Generally, the colloid of LED is epoxy resin. LEDs with UV resistance and flame retardancy are more expensive. 8. Chip size: the chip size is represented by the side length. Big chip major Intelligent factory lighting Its quality is better than that of small chips. The price is proportional to the chip size. 9. Radiator: The radiator can see the appearance of the lamp. Temperature will affect the life of LED lamp beads. Counting plays a vital role. 10. Power supply: According to the plan requirements of different manufacturers, it can be divided into two types: constant current power supply and constant voltage power supply.

The life of LED mining lamp depends largely on the level of heat dissipation, and the main way to improve the level of heat dissipation is to transfer the excess heat generated by the chip through the radiator and radiator. At the same time, major Intelligent factory lighting The main parameters related to LED heat dissipation are thermal resistance, junction temperature, temperature rise, etc. Thermal resistance is the quotient obtained by dividing the difference between the effective temperature of the equipment and the temperature of the external designated reference point by the steady-state power consumption in the equipment. It is an important parameter indicating the degree of heat dissipation of equipment. Junction temperature refers to the temperature of the semiconductor junction of the main heating part in the LED device. It reflects major Intelligent factory lighting Temperature value that can be withstood under working conditions. Temperature rise refers to the temperature rise of the enclosure environment. It refers to the difference between the temperature of LED equipment shell and the ambient temperature. This is a temperature value that can be directly measured, which can directly reflect the heat dissipation degree around LED devices.