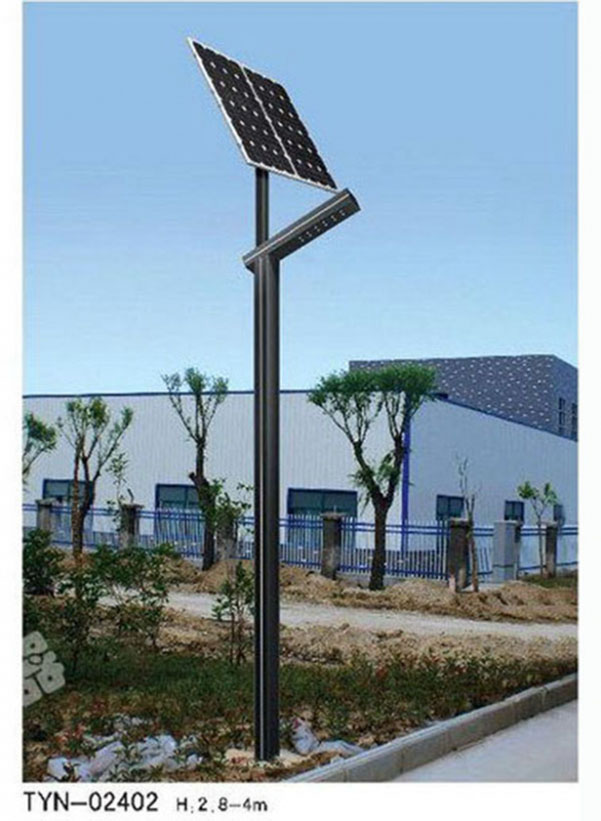

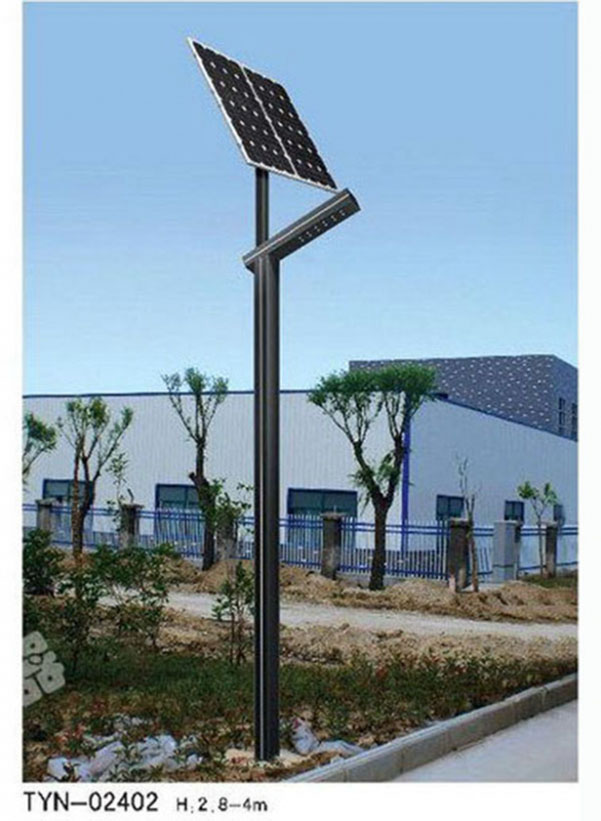

(1) There are potential safety hazards in municipal lighting: due to the construction quality, garden engineering transformation, aging materials, abnormal power supply, water and electricity pipeline conflict, many potential safety hazards have been brought. (2) Solar street lamps are energy-saving and environment-friendly new energy power generation products. There is no electricity bill. High electricity charge for mains lighting: major Industrial lighting Our jobs have fixed and high electricity bills. Solar lighting is free of electricity charge: solar road lighting is a one-time investment without any maintenance costs, the investment cost can be recovered within three years, and has long-term benefits. (3) major Industrial lighting The installation of the solar street lamp is very simple: when installing the solar street lamp, you don't need to lay complex lines, just make a cement base and fix it with stainless steel screws. The installation of municipal lighting fixtures is very complicated: there are complex operating procedures in the municipal lighting project.

1、 Disconnection. For "dead light", we should first determine major Industrial lighting Is it short circuit or open circuit. 2、 The adhesive layer is peeled off. For some LED energy-saving project lights with vertical chips, the common reasons for dead lights are the peeling off of the bottom of the chip bonding layer and the peeling off of the bracket coating. 3、 The welding spot is burnt. In some cases, the dead light of the bulb may not be caused by the bulb itself, but also by the power supply used. 4、 Chip corrosion. The previous energy-saving floodlights and energy-saving floodlights are open circuit. The following is the condition of short circuit dead light. major Industrial lighting There are many reasons for dead lights. Dead light may appear in every link from packaging, application to use.

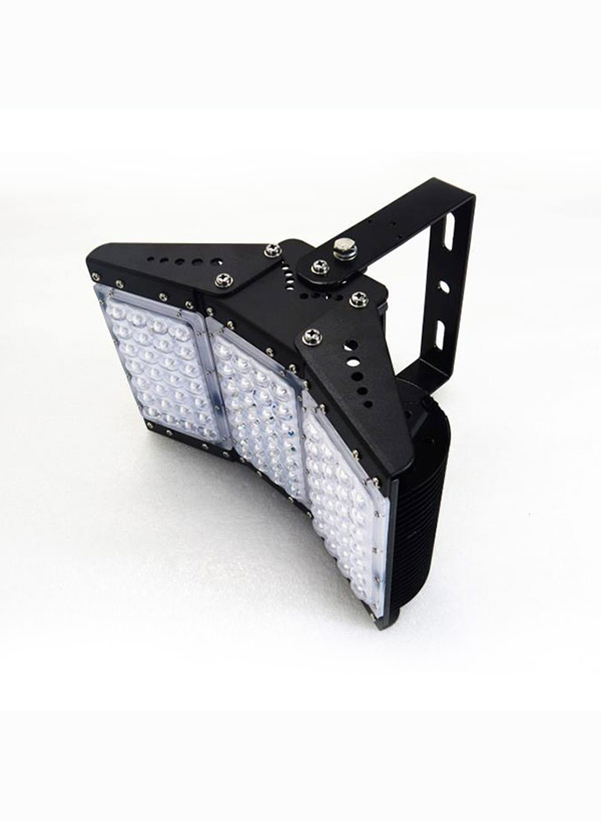

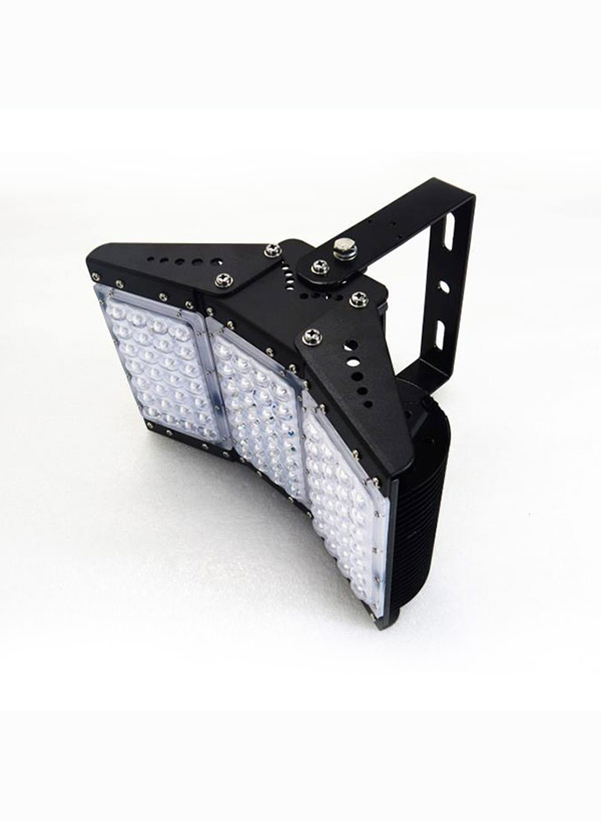

(1) Recommended installation height of 50W LED energy-saving mining lamp: 3-5 meters; Installation distance: 5-8m. (2) Recommended installation height of 100W LED energy-saving mining lamp: 6-8m; Installation distance: 8-10 m. (3) 120W LED energy-saving mining lamp Recommended installation height: 8-10m; Installation distance: 8-10 m. (4)150W major Industrial lighting Recommended installation height: 10-15m; Installation distance: 8-12m. (5) major Industrial lighting 200W Recommended installation height: 10-15m; Installation distance: 10-15m. (6) LED energy-saving mining lamp 300W recommended installation height: 15-20m; Installation distance: 20-25m. (7) Recommended installation height of 450W LED energy-saving mining lamp: 15-20m; Installation distance: 25-30m

The life of LED mining lamp depends largely on the level of heat dissipation, and the main way to improve the level of heat dissipation is to transfer the excess heat generated by the chip through the radiator and radiator. At the same time, major Industrial lighting The main parameters related to LED heat dissipation are thermal resistance, junction temperature, temperature rise, etc. Thermal resistance is the quotient obtained by dividing the difference between the effective temperature of the equipment and the temperature of the external designated reference point by the steady-state power consumption in the equipment. It is an important parameter indicating the degree of heat dissipation of equipment. Junction temperature refers to the temperature of the semiconductor junction of the main heating part in the LED device. It reflects major Industrial lighting Temperature value that can be withstood under working conditions. Temperature rise refers to the temperature rise of the enclosure environment. It refers to the difference between the temperature of LED equipment shell and the ambient temperature. This is a temperature value that can be directly measured, which can directly reflect the heat dissipation degree around LED devices.